新聞中心

如何正確選擇滾珠絲桿支撐座呢?

來源:http://www.306135.com/ 日期:2020-10-15 發布人:

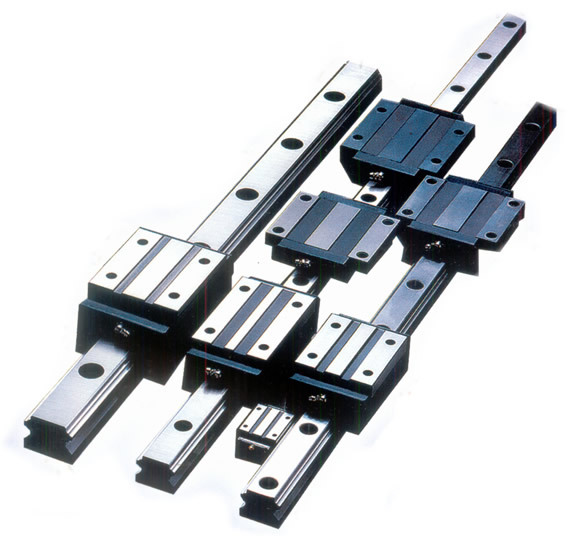

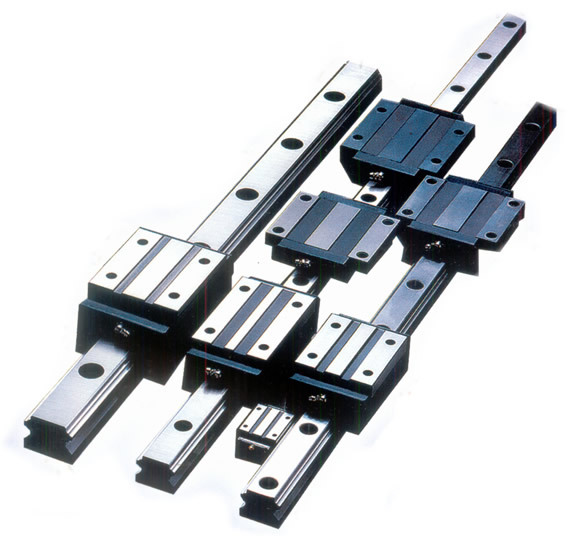

伴隨著工業改革機制,自動化機械手廠家越來越多,則需要絲桿支撐座部件的也就越多,目前市場上的型號各式各樣,千奇百態,有研磨、有冷軋,如何區分,選擇合適自己的呢? 我們來聽一下技術人員的分析,那么如何正確選擇滾珠絲桿支撐座呢?

With the industrial reform mechanism, there are more and more automatic manipulator manufacturers, and more and more screw rod support seat components are needed. At present, there are various types of models on the market, including grinding and cold rolling. How to distinguish and choose the appropriate one? Let's listen to the technical personnel's analysis, then how to correctly select the ball screw support seat?

一、我們要清楚標準型滾珠絲桿支撐座的規格定義,通常絲桿軸承座產品代號,可分為固定座AK、BK、EK、FK,支撐座AF、BF、EF、FF等八種型式。

1、 We should make clear the specification and definition of the standard ball screw support seat. Generally, the product code of screw rod bearing seat can be divided into eight types: fixed seat AK, BK, EK, FK, and support seat AF, BF, EF, FF.

軸承座公稱軸徑,為固定端軸承座的內徑,為兩碼數字,單位為mm,例如30為內徑30mm;35為內徑35mm;支撐端軸承座的公稱軸徑是指相對應固定端軸承的公稱軸徑,支撐端軸承座的軸承內徑等于或小于公稱軸徑。

The nominal shaft diameter of the bearing block is the inner diameter of the fixed end bearing block, which is a two yard number, and the unit is mm. For example, 30 is the inner diameter of 30mm; 35 is the inner diameter of 35mm; the nominal shaft diameter of the support end bearing block refers to the nominal shaft diameter of the corresponding fixed end bearing, and the bearing inner diameter of the bearing support end is equal to or less than the nominal shaft diameter.

二、軸承形式,空白表示為標準規格,一般系使用30°接觸角軸承(A型),但公稱軸徑35及40的規格因為較高軸向負荷需求,特別使用40°接觸角軸承;B為40°接觸角軸承;但只有公稱軸徑20mm(含)以上的規格才有40°接觸角軸承的設計。

2、 Bearing form, blank is expressed as standard specification. Generally, 30 ° contact angle bearing (type A) is used, but 40 ° contact angle bearing is specially used for specifications with nominal shaft diameter of 35 and 40 due to higher axial load demand; B is 40 ° contact angle bearing; however, 40 ° contact angle bearing is only designed for specifications with nominal shaft diameter of more than 20 mm (including).

三、C3:軸承座等級,分為C3、C5、C7三種級數。建議C3級絲桿選用C級軸承座,C5級絲桿選用C5級或C3級軸承座,以使軸承座的精度可以和絲桿的精度匹配;而C7級絲桿建議只需選用C7級軸承座即可。

3、 C3: bearing pedestal grade, divided into C3, C5 and C7. It is suggested that grade C bearing block should be used for C3 screw rod, C5 or C3 bearing seat should be selected for C5 screw rod, so that the accuracy of bearing seat can match with that of screw rod; and C7 screw rod only needs C7 bearing seat.

四、表面處理,分為染黑和表面鍍鎳兩種,標準品為染黑處理,不標記表面處理符號;而表面鍍鎳處理者,表面處理符號標記為N,但表面鍍鎳者無庫存,采取2訂單式生產。

4、 The surface treatment is divided into two types: black staining and nickel plating. The standard product is dyed black, and the surface treatment symbol is not marked; while for the surface nickel plating treatment, the surface treatment symbol is marked as N, but the surface nickel plating person has no stock, and adopts 2-order production.

聽了上述我們工程師的分析,相信各位在對絲桿軸承座選型的時候,都知道該怎么區分和對應了,當然在實際運作中,有哪些不清楚的地方,可以關注公司網站:http://www.306135.com。

After listening to the above analysis of our engineers, I believe that you all know how to distinguish and correspond when selecting the type of screw rod bearing pedestal. Of course, in actual operation, if there are any unclear points, please pay attention to the company's website: http://www.306135.com 。

導軌絲杠:從設計結構...<>

導軌絲杠:從設計結構...<> 大型絲杠的性能設計介...<>

大型絲杠的性能設計介...<> 梯形絲杠和滾珠絲杠的...<>

梯形絲杠和滾珠絲杠的...<> 滾珠絲桿目前的行業的...<>

滾珠絲桿目前的行業的...<> 滾珠絲杠螺母油封更換...<>

滾珠絲杠螺母油封更換...<>

相關: