新聞中心

導軌絲杠對于數控機床導軌有哪些特性

來源:http://www.306135.com/ 日期:2020-10-29 發布人:

機床制造者較關心的莫過于機床的精度,剛性和使用壽命,對導軌系統的關注甚少。但導軌為機床功能的實現奠定了可靠的基礎。各種類型的機床工作部件,都是利用控制軸在指定的導軌上運動,機床設計者根據機床的類型和用途選用各種不同形式的導軌系統,用得較為廣泛的有下列三種:即平面導軌、直線滾動導軌和循環滾柱與平面導軌的組合所構成的滾動體導軌。下面就來和導軌絲桿小編一起來了解一下數控機床導軌的種類和特性吧。

Machine tool manufacturers are more concerned about the accuracy, rigidity and service life of the machine tool, and pay little attention to the guide rail system. However, the guideway lays a reliable foundation for the realization of machine tool functions. Various types of machine tool working parts use the control axis to move on the designated guide rail. The designer of the machine tool selects various forms of guide rail system according to the type and use of the machine tool. There are three kinds of guide rail widely used: plane guide rail, linear rolling guide rail and rolling body guide rail composed of circular roller and plane guide rail. Next, let's learn about the types and characteristics of CNC machine tool guideway together with guide screw.

一、導軌的功能

1、 Function of guide rail

盡管導軌系統的形式是多種多樣的,但工作性質都是相同的,機床工作部件在指定導軌系統上移動,尤如火車沿著鐵軌在指定的方向上行駛。主要體現如下三種基本功能:

Although the form of the guide rail system is various, but the nature of the work is the same. The working parts of the machine tool move on the specified guide system, such as the train running along the rail in the specified direction. It mainly embodies the following three basic functions:

1、為承載體的運動導向;

1. Guide the movement of the bearing body;

2、為承載體提供光滑的運動表面;

2. Provide smooth moving surface for the bearing body;

3、把機床的切削所產生的力傳到地基或床身上,減少產生的沖擊對被動加工零件的影響。沿導軌系統的運動,大多數為直線運動,也有少數為弧線運動。直線導軌的很多技術可以直接應用弧形導軌。

3. The force generated by the cutting of the machine tool is transmitted to the foundation or bed to reduce the impact on the passive machining parts. Most of the motion along the guide rail system is linear motion, and a few are arc motion. Many technologies of linear guideway can be directly applied to arc guideway.

導軌絲桿

Guide screw

二、導軌的分類

2、 Classification of guide rails

機床制造廠都在盡較大的努力,確保導軌安裝的精確性。導軌被加工前,導軌和工作部件都已經過時效處理,以內應力。為了保證導軌的精度和延長使用壽命,刮研是一種常用的工藝方法。

Machine tool manufacturers are making great efforts to ensure the accuracy of rail installation. Before the guide rail is processed, the guide rail and working parts have been aged to eliminate internal stress. In order to ensure the accuracy of the guide rail and prolong the service life, scraping is a common technology.

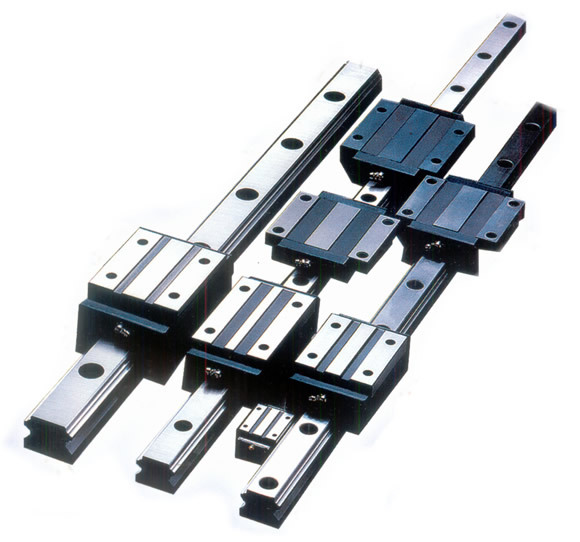

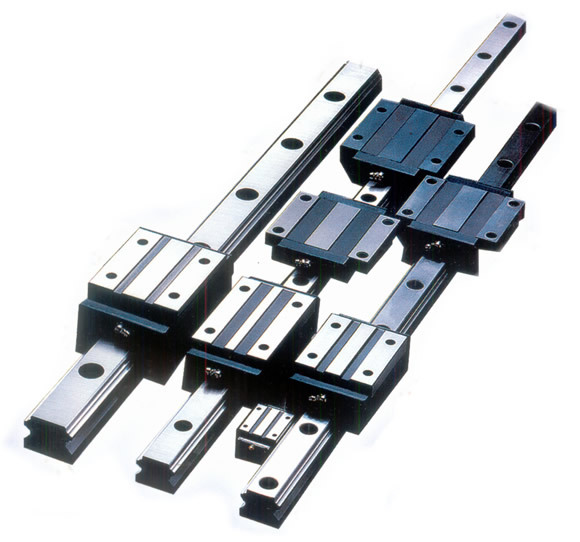

1、直線導軌

1. Linear guide

新的導軌系統使機床可獲得快速進給速度,在主軸轉速相同的情況下,快速進給是直線導軌的特點。直線導軌與平面導軌一樣,有兩個基本元件;一個作為導向的為固定元件,另一個是移動元件。為了保證機床的精度,床身或立柱少量的刮研是必不可少的,一般情況下,安裝比較簡單。

The new guideway system enables the machine tool to obtain rapid feed rate. Under the condition of the same spindle speed, rapid feed is the characteristic of linear guide. Like plane guide, linear guide has two basic elements: one is fixed element, the other is moving element. In order to ensure the accuracy of the machine tool, a small amount of scraping and grinding of the bed or column is necessary. In general, the installation is relatively simple.

直線導軌的移動元件和固定元件之間不用中間介質,而用滾動鋼球。因為滾動鋼球適應于高速運動、摩擦系數小、靈敏度高,滿足運動部件的工作要求,如機床的刀架,拖板等。

There is no intermediate medium between the moving element and the fixed element of linear guide, but rolling steel ball is used. Because the rolling steel ball is suitable for high-speed movement, small friction coefficient and high sensitivity, it can meet the working requirements of moving parts, such as tool rest and carriage of machine tool.

工作時間過長,鋼球開始磨損,作用在鋼球上的預加負載開始減弱,導致機床工作部件運動精度的降低。如果要保持初始精度,必須更換導軌支架,甚更換導軌。鈦浩機械是以回轉、絲杠、機床主軸、軸加工、高精刀柄、刀桿、彈性夾頭、非標件加工、機床接桿為公司的主打產品!如果導軌系統已有預加負載作用。系統精度已喪失,的方法是更換滾動元件。

When the working time is too long, the steel ball begins to wear, and the preload acting on the steel ball begins to weaken, which leads to the reduction of the movement accuracy of the working parts of the machine tool. If the initial accuracy is to be maintained, the guide rail bracket must be replaced, or even the guide rail. Tihao machinery is the company's main products, such as rotary center, lead screw, machine tool spindle, shaft processing, high-precision toolholder, cutter bar, elastic chuck, non-standard parts processing and machine tool extension bar. If the guide rail system has preloading effect. The accuracy of the system has been lost, and the only way is to replace the rolling element.

2、直線滾柱導軌

2. Linear roller guide

直線滾柱導軌系統是平面導軌與直線滾柱導軌的組合,用滾柱安裝在平行導軌上,用滾柱代鋼球承載機床的運動部件。優點是接觸面積大、承載負荷大、靈敏度高。從床身尾部看,支架與滾柱置于平面導軌的頂面和側面,為了獲得高精度,在機床工作部件和支架內面之間,設置一塊楔板,使預加負載作用于支架的側面。楔板的工作原理與斜鐵相似,工作部件的重量作用于支架的頂面。由于作用在導軌系統上的預加負荷是可調的,為此楔板的損失得到補償,這一特點被廣泛用于中型或大型機床上,因為它對CNC指令反應靈敏,承受負荷大,直線滾柱導軌系統比傳統的平面導機能經受高速運轉,改善機床的性能。

The linear roller guide rail system is a combination of plane guide rail and linear roller guide rail. The roller is installed on the parallel guide rail, and the roller is used to replace the steel ball to carry the moving parts of the machine tool. The advantages are large contact area, large load bearing capacity and high sensitivity. From the end of the bed, the support and roller are placed on the top and side of the plane guide rail. In order to obtain high precision, a wedge plate is set between the working parts of the machine tool and the inner surface of the support to make the preload act on the side of the support. The working principle of wedge plate is similar to that of inclined iron, and the weight of working parts acts on the top surface of support. Because the preload acting on the guide rail system is adjustable, the loss of wedge plate can be compensated. This feature is widely used in medium or large machine tools, because it is sensitive to CNC instructions and bears large load. The linear roller guide system can withstand high speed operation than the traditional plane guide function and improve the performance of the machine tool.

導軌絲桿

Guide screw

3、鑲鋼導軌

3. Steel inlaid guide rail

機床上較常用的導軌形式是鑲鋼導軌,它的使用已有很長的歷史。鑲鋼導軌是導軌系統的固定元件,其截面為矩形。它可水平裝在機床的床身上,也可以與床身鑄成一體,分別被稱為鑲鋼式或整體式。鑲鋼式導軌是由鋼制成的,經淬硬和磨削。硬度在洛氏硬度60度以上、把鑲鋼導軌用螺釘或粘結劑(環氧樹脂)貼在機床床身或經刮研的立柱配合表面上,確保導軌獲得較佳的平面度。這種形式,維修更換方便、簡單,很受維修工人的歡迎。

Inlaid steel guideway is the most commonly used guide rail on machine tools, which has been used for a long time. The steel inlaid guide rail is a fixed component of the guide rail system, and its cross section is rectangular. It can be installed horizontally on the bed of the machine tool, and can also be cast into one body with the bed. It is called inlaid steel type or integral type respectively. The steel inlaid guide rail is made of steel, hardened and ground. If the hardness is above 60 degrees of Rockwell hardness, stick the steel inlaid guide rail with screws or adhesive (epoxy resin) on the machine tool bed or the matching surface of the column after scraping, so as to ensure the guide rail to obtain better flatness. This form is convenient and simple for maintenance and replacement, and is very popular with maintenance workers.

4、滑動導軌

4. Slide guide

傳統導軌的發展,表現在滑動元件和導軌形式上,滑動導軌的特點是導軌和滑動件之間使用了介質,形式的不同在于選擇不同的介質。

The development of the traditional guide rail, first of all, is shown in the form of sliding elements and sliding elements. The characteristic of sliding guide rail is that the medium is used between the guide rail and the sliding part. The difference in the form lies in the selection of different media.

以上就是導軌絲桿對于數控機床導軌的種類和特性介紹,如果您有什么不同的意見或者建議可以聯系我們,或在我們網站留言http://www.306135.com。

The above is the guide screw for CNC machine tool guide types and characteristics, if you have any different opinions or suggestions, you can contact us, or leave a message on our website http://www.306135.com 。

- 上一篇:直線導軌熱點校直要注意哪幾個問題

- 下一篇:滾珠絲桿的安裝過程

導軌絲杠:從設計結構...<>

導軌絲杠:從設計結構...<> 大型絲杠的性能設計介...<>

大型絲杠的性能設計介...<> 梯形絲杠和滾珠絲杠的...<>

梯形絲杠和滾珠絲杠的...<> 滾珠絲桿目前的行業的...<>

滾珠絲桿目前的行業的...<> 滾珠絲杠螺母油封更換...<>

滾珠絲杠螺母油封更換...<>

相關: