新聞中心

軸承出現異常噪音怎么回事?

來源:http://www.306135.com/ 日期:2021-04-14 發布人:

軸承作為機械設備的主要零部件,在運行過程中使用性能質量直接會影響到機械設備正常運行的性能。軸承運行過程中發生異常狀態是在所難免的,常見的異常狀態主要有噪音,異常的溫度上升,震動大(軸的跳動)和潤滑劑泄漏過多、變色等。今天給大家分享的是軸承使用過程中出現異常噪音相應的種類與應對措施,希望對大家有所幫助。

As the main parts of mechanical equipment, the performance quality of bearings in the operation process will directly affect the normal operation performance of mechanical equipment. It is inevitable that abnormal state occurs in the process of bearing operation. The common abnormal state mainly includes noise, abnormal temperature rise, large vibration (shaft runout), excessive lubricant leakage and discoloration. Today I would like to share with you the types and Countermeasures of abnormal noise in the process of bearing use, hoping to help you.

軸承若處于良好的連轉狀態會發出低低的嗚嗚或嗡嗡聲音。若是發出尖銳的嘶嘶音、吱吱音或其它不規則的聲音,則很有可能表示軸承處于不良的連轉狀況。尖銳的吱吱噪音可能是由于不適當的潤滑所造成的。不適當的軸承間隙也會造成金屬聲。

If the bearing is in a good continuous running state, it will make a low whine or buzzing sound. If there is a sharp hiss, squeak or other irregular sound, it is likely to indicate that the bearing is in a bad continuous running condition. Sharp squeaking noise may be caused by improper lubrication. Improper bearing clearance can also cause metallic noise.

常見的軸承運行異常噪音主要三種情況,分別為:大的金屬噪音、規則的噪音和不規則噪音。

There are three kinds of common abnormal noise in bearing operation: large metal noise, regular noise and irregular noise.

01大的金屬噪音

01 heavy metal noise

造成軸承發出大的金屬噪音主要原因有異常負荷、安裝不良、潤滑劑不足、不適合等。針對軸承異常負荷的對策:修正配合,研究軸承游隙,調整預負荷,修正外殼擋肩位置。針對軸承安裝不良的對策:提高軸、軸承座的加工精度,改善安裝精度、安裝方法。針對軸承潤滑劑不足的對策:補充潤滑劑,選擇恰當的潤滑劑。

The main reasons for the heavy metal noise of the bearing are abnormal load, poor installation, insufficient lubricant, unsuitable, etc. Countermeasures for abnormal load of bearing: correct fit, study bearing clearance, adjust preload and correct housing shoulder position. The Countermeasures for the poor installation of bearings are to improve the machining accuracy of shaft and bearing seat, and improve the installation accuracy and installation method. In view of the bearing lubricant insufficiency countermeasure: supplements the lubricant, chooses the suitable lubricant.

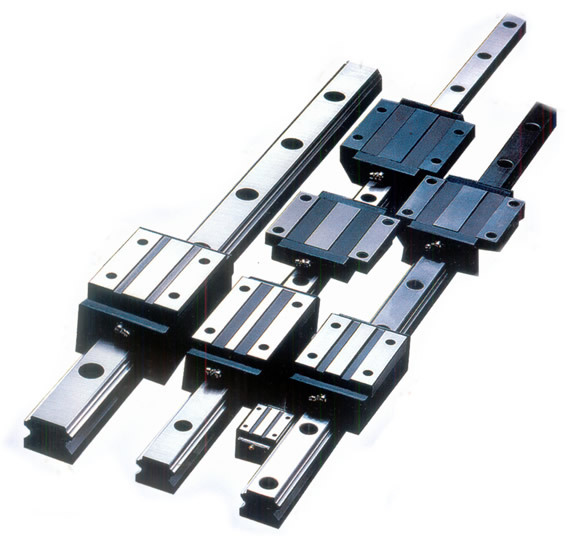

導軌絲杠

Guide screw

02規則噪音

02 regular noise

有時軸承在運轉過程中會發生“呲啦-呲啦“的聲音”,斷斷續續,并有規則的發生,這種就屬于規則的噪音。造成軸承產生規則噪音的原因主要有:由于異物滾動面產生壓痕、銹、傷痕,(鋼滲碳后)表面變形和滾道面斷裂。

Sometimes the bearing in the process of operation will occur "Yila - Yila" sound, intermittent, and regular occurrence, this belongs to the rule of noise. The main causes of bearing regular noise are: indentation, rust and scar on rolling surface caused by foreign matters, surface deformation (after carburizing) and raceway surface fracture.

針對異物滾動面產生壓痕、銹、傷痕的軸承對策:更換軸承,清洗有關零件,改善密封裝置,使用干凈的潤滑劑。針對軸承(鋼滲碳后)表面變形的對策:更換軸承并注意其使用。針對軸承滾道面斷裂的對策:更換軸承。

Bearing countermeasures for indentation, rust and scar on rolling surface of foreign matters: replace bearing, clean relevant parts, improve sealing device, and use clean lubricant. Countermeasures for surface deformation of bearing (Steel Carburized): replace the bearing and pay attention to its use. The countermeasure for the fracture of bearing raceway surface is to replace the bearing.

03不規則噪音

03 irregular noise

如果軸承運行中發生“吱啦吱啦”的聲音,并且不會隨著回轉速度變化而變化,這種情況就屬于不規則噪音,多見于小型軸承上。導致這種情況的主要有:游隙過大、異物侵入和球的損傷、斷裂。針對軸承游隙過大的對策:研究配合及軸承游隙,修改預負荷量。針對軸承發生異物侵入的對策:研究更換軸承,清洗有關零件,改善密封裝置,使用干凈的潤滑劑。

If the "creak" sound occurs in the operation of the bearing, and it will not change with the change of rotation speed, this situation belongs to irregular noise, which is more common in small bearings. The main causes of this situation are: excessive clearance, foreign body invasion and ball damage, fracture. For the bearing clearance is too large countermeasures: research fit and bearing clearance, modify the preload. In view of the bearing foreign matter invasion countermeasure: Research replacement bearing, cleaning related parts, improving sealing device, using clean lubricant.

導軌絲杠:從設計結構...<>

導軌絲杠:從設計結構...<> 大型絲杠的性能設計介...<>

大型絲杠的性能設計介...<> 梯形絲杠和滾珠絲杠的...<>

梯形絲杠和滾珠絲杠的...<> 滾珠絲桿目前的行業的...<>

滾珠絲桿目前的行業的...<> 滾珠絲杠螺母油封更換...<>

滾珠絲杠螺母油封更換...<>

相關: