新聞中心

在數控切割機中如何調整直線導軌?

來源:http://www.306135.com/ 日期:2021-05-20 發布人:

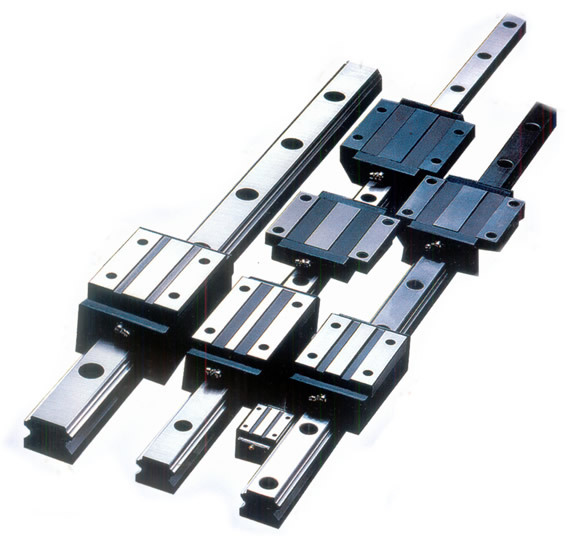

直線導軌是數控切割機較重要的部分。它是用于線性往復運動的東西。該東西具有以前的直線軸承所沒有的較高的額外載荷,并且還能夠承當必定的負載。扭矩還能夠在高負載條件下實現高精度的直線運動,使設備平穩,準確地運行。

Linear guide is an important part of CNC cutting machine. It's something for linear reciprocating motion. It has a higher additional load than the previous linear bearing, and can also bear a certain load. Torque can also achieve high-precision linear motion under high load conditions, so that the equipment runs smoothly and accurately.

數控切割機上的直線導軌和直線軸是數控切割機的核心部件之一。它的功能是指導和支持。為保證數控切割機加工精度高,需求導軌和直線具有較高的導向精度和較好的運動穩定性。

The linear guide and linear axis of CNC cutting machine is one of the core components of CNC cutting machine. Its function is guidance and support. In order to ensure high machining accuracy of CNC cutting machine, guide rail and straight line are required to have higher guiding accuracy and better motion stability.

較遍及的是由平面導軌,直線導軌以及循環滾子和平面導軌的組合形成的滾動體引導件。盡管有多種類型的導軌,但大部分的工作特性是相同的,為載體提供了一個潤滑的移動外表。處理由機床切削產生的力以減小對被迫加工零件的影響。

More widely by the plane guide, linear guide and the combination of circular roller and plane guide to form a rolling element guide. Although there are many types of guides, most of the operating characteristics are the same, providing a lubricating moving surface for the carrier. To deal with the force generated by the machine tool cutting to reduce the impact on the forced processing parts.

大多數導軌是直線運動,少量是弧形運動。直線導軌經過精 確的加工程序與滾珠相結合。其運動速度快,摩擦系數小,靈敏度高,滿足運動部件的工作要求。滾動體怎么與軌跡外表觸摸是較直接影響系統功能的主要因素之一。

Most of the guide rail is linear motion, a small number of arc motion. The linear guide is combined with the ball through the precise machining procedure. It has the advantages of high speed, small friction coefficient and high sensitivity, which can meet the working requirements of moving parts. How to touch the surface of the rolling element with the track is one of the main factors that directly affect the function of the system.

直線導軌能夠使CNC切割機取得快速進給速度。在主軸轉速相同的情況下,快速進給是直線導軌的特征。那么咱們需求怎么調整直線導軌?

The linear guide can make the CNC cutting machine achieve fast feed speed. In the case of the same spindle speed, rapid feed is the feature of linear guide. So how do we need to adjust the linear guide?

具體操作如下:

The specific operation is as follows:

1.在導軌兩頭擰緊1/2000mm規范鋼絲,調整導軌上兩個導向板上的調整螺釘,使導軌兩邊與規范鋼絲之間的間隔為a必定的值,并將此間隔用作規范間隔。

1. Tighten the 1 / 2000mm standard steel wire at both ends of the guide rail, adjust the adjusting screws on the two guide plates on the guide rail, so that the interval between both sides of the guide rail and the standard steel wire is a certain value, and use this interval as the standard interval.

2,用20N的拉力,拉伸精度為1/2000mm的鋼卷尺,兩頭主,副導軌之間的間隔應為機器的跨度,不然運用整根導線調整導軌,同時調整導線以保證規范間隔不會改變。

2. For the steel tape with tensile force of 20n and drawing accuracy of 1 / 2000mm, the interval between the main and auxiliary guide rails at both ends shall be the span of the machine, otherwise, the whole wire shall be used to adjust the guide rail, and the wire shall be adjusted at the same time to ensure that the standard interval will not change.

3.以1/10000毫米的精度測量主 導軌和副導軌兩頭的平整度,并調整導螺栓的高度以調整高度,使主 導軌和副導軌的平整度兩頭的導軌保持在0.5毫米以內。

3. Measure the flatness of the two ends of the main guide rail and the auxiliary guide rail with the accuracy of 1 / 10000 mm, and adjust the height of the guide bolt to adjust the height, so that the flatness of the two ends of the main guide rail and the auxiliary guide rail is kept within 0.5 mm.

4.運用壓板緊縮端部的每個主軌跡和輔佐軌跡,作為調整軌跡水平緩筆直水平狀態的根底,主軌跡和副軌跡的平坦度以及主軌跡和副軌跡之間的間距子導軌。鋼軌的直線度是鋼。導線和導軌旁邊面之間的規范間隔是參考。

4. Each main track and auxiliary track at the compression end of the pressing plate are used as the basis for adjusting the horizontal state of the track, the flatness of the main track and the auxiliary track, and the spacing between the main track and the auxiliary track. The straightness of rail is steel. The gauge interval between the conductor and the side surface of the guide rail is a reference.

5.用調 理銷和探針腳逐一調 理每個主 導軌兩頭和規范鋼絲繩之間的間隔,并將其調整到規范間隔。

5. Adjust the interval between the two ends of each main guide rail and the standard wire rope one by one with the adjusting pin and probe foot, and adjust it to the standard interval.

6.運用氣泡調平器調整導軌的水平緩筆直水平。從導軌的一端逐漸校準到另一端,然后測量兩個導軌的接頭,以保證它們處于水平位置。

6. Use bubble leveler to adjust the level of guide rail. Gradually align the rails from one end to the other, and then measure the joints of the two rails to ensure that they are in a horizontal position.

7.校準主,輔 導軌后,當心擰緊導軌間的連接螺栓,用壓板壓住導軌。仔細檢查導軌是否允許移動或變形。導軌接頭的水平緩旁邊面應保持潤滑。

7. After calibrating the main and guide rails, carefully tighten the connecting bolts between the guide rails, and press the guide rails with pressing plates. Carefully check whether the guide rail is allowed to move or deform. The horizontal surface of the rail joint shall be lubricated.

以上信息是我們導軌絲杠整理發布希望對大家有所幫助我們的網站是:http://www.306135.com!

The above information is our guide screw finishing release, I hope to help you. Our website is: http://www.306135.com !

- 上一篇:滾珠絲桿導軌滑軌選潤滑脂的技巧

- 下一篇:導軌絲杠直線度誤差檢測你知道嗎?

導軌絲杠:從設計結構...<>

導軌絲杠:從設計結構...<> 大型絲杠的性能設計介...<>

大型絲杠的性能設計介...<> 梯形絲杠和滾珠絲杠的...<>

梯形絲杠和滾珠絲杠的...<> 滾珠絲桿目前的行業的...<>

滾珠絲桿目前的行業的...<> 滾珠絲杠螺母油封更換...<>

滾珠絲杠螺母油封更換...<>

相關: