新聞中心

直線導軌如何清楚渣滓粉塵

來源:http://www.306135.com/ 日期:2021-06-30 發布人:

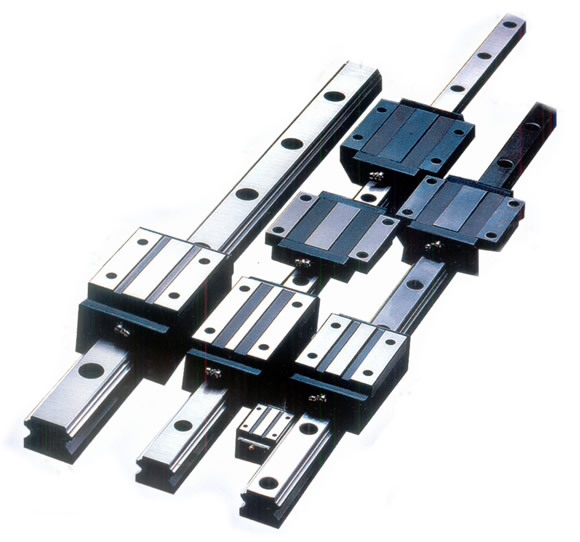

直線導軌中的直線軸作為設備的核心部件之一,是起導向和支承作用。為了能夠使機器有較高的加工度,要求其導軌、直線具有較高的導向和良好的運動平穩性。

As one of the core parts of the equipment, the linear axis in the linear guide rail plays a guiding and supporting role. In order to make the machine have a higher degree of processing, the guide rail and straight line are required to have higher guidance and good motion stability.

直線導軌在運行過程中,在加工中會產生大量的腐蝕性粉塵和渣滓,這些渣滓和粉塵就會沉積于導軌、直線軸表面,長期以往的積累,對設備的加工會產生很大的影響,并且會在導軌直線軸表面形成蝕點,這樣就會縮短設備使用壽命。

During the operation of linear guide rail, a large amount of corrosive dust and dross will be produced in the process of processing. These dross and dust will deposit on the surface of guide rail and linear axis. The long-term accumulation will have a great impact on the processing of equipment, and will form corrosion spots on the surface of linear axis of guide rail, which will shorten the service life of equipment.

清潔前要準備潤滑油、干棉布。把橫梁移動到內側,打開機器兩側端蓋,找到導軌,用干棉布把兩側導軌與滾輪接觸的地方擦拭干凈,再移動橫梁,把剩余地方清潔干凈把激光頭移動到右側(或左側),找到直線導軌,用干棉布擦拭直到光亮無塵,再加上少許潤滑油(切勿使用機油),將激光頭左右慢慢推動幾次,讓潤滑油均勻分布即可。

Prepare lubricating oil and dry cotton cloth before cleaning. Move the crossbeam to the inside, open the end covers on both sides of the machine, find the guide rail, wipe the contact area between the guide rail and the roller with dry cotton cloth, then move the crossbeam to clean the rest, move the laser head to the right (or left), find the linear guide rail, wipe it with dry cotton cloth until it is bright and dust-free, and add a little lubricating oil (do not use engine oil), Push the laser head left and right slowly for several times to evenly distribute the lubricating oil.

- 上一篇:直線導軌的工作原理和防塵防銹清潔

- 下一篇:滾珠絲桿零部件的組裝要注意什么?

導軌絲杠:從設計結構...<>

導軌絲杠:從設計結構...<> 大型絲杠的性能設計介...<>

大型絲杠的性能設計介...<> 梯形絲杠和滾珠絲杠的...<>

梯形絲杠和滾珠絲杠的...<> 滾珠絲桿目前的行業的...<>

滾珠絲桿目前的行業的...<> 滾珠絲杠螺母油封更換...<>

滾珠絲杠螺母油封更換...<>

相關: