新聞中心

精密滾珠絲杠軸向跳動嚴重超差的原因

來源:http://www.306135.com/ 日期:2023-03-18 發布人:

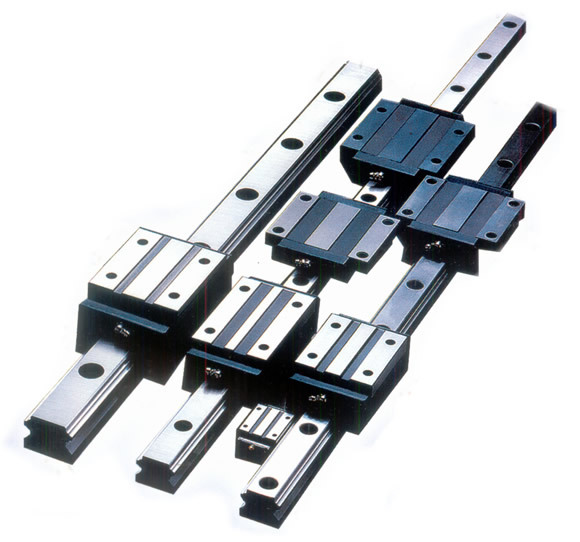

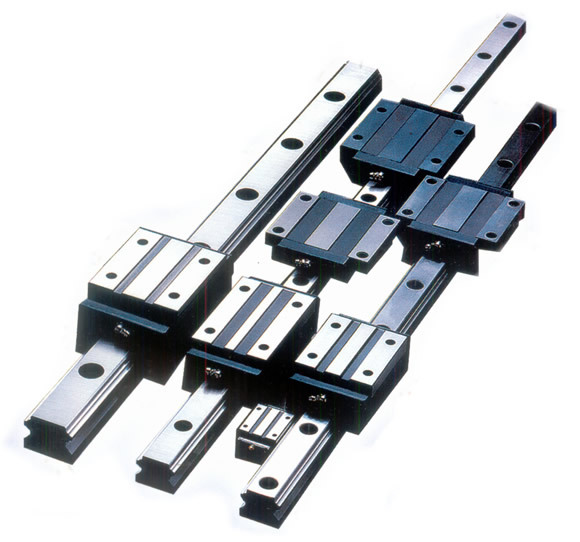

數控車床精密滾珠絲杠裝配后進行靜態精度檢查時合格,但在試車后或使用一段時間后出現精密滾珠絲杠的軸向跳動嚴重超差,影響了機床的加工精度,設備返修率為43%,給企業帶來巨大的經濟損失和聲譽損失。下面導軌絲杠廠家為您分析:

After assembling the precision ball screw of a CNC lathe, it passed the static accuracy inspection, but the axial runout of the precision ball screw occurred after a test run or after a period of use, seriously exceeding the tolerance, affecting the machining accuracy of the machine tool. The equipment repair rate is 43%, bringing huge economic losses and reputation losses to the enterprise. The following guide rail lead screw manufacturers analyze for you:

1.精密滾珠絲杠精度達不到要求

1. Precision ball screw accuracy cannot meet the requirements

滾珠絲杠在入庫時已進行了精度檢驗,可排除本身的質量問題。但細長軸類零件(機床絲桿等)在保管時應該采用垂直放置,以免受重力變形影響精度。該滾珠絲杠采專用包裝箱垂直放置,在裝配后的靜態檢查合格,因此可以排除此項。

The accuracy of the ball screw has been inspected before warehousing, which can eliminate its own quality problems. However, when storing slender shaft parts (machine tool screw rods, etc.), they should be placed vertically to avoid gravity deformation affecting accuracy. The ball screw is vertically placed in a special packaging box and passes the static inspection after assembly, so this item can be excluded.

2.裝配不當損壞了絲杠的精度

Improper assembly damages the accuracy of the lead screw

通過了解,裝配工人對精密滾珠絲杠組件熟悉的,裝配時也是格外小心,完全按裝配工藝進行的,因此也排除了這種可能。

Through understanding, assembly workers are familiar with precision ball screw components, and they are also extremely careful when assembling, completely following the assembly process, thus eliminating this possibility.

3.機床行程超程,工作臺發生碰撞,導致精度損壞

3. The machine tool stroke exceeds the range, and the workbench collides, resulting in accuracy damage

操作機床時發生超程,容易導致機床碰撞而引起的。但經了解機床的行程限位開關沒有問題,用戶也沒有這方面的意見反饋。

Overtravel occurs when operating the machine tool, which is easily caused by machine tool collision. However, it is understood that there is no problem with the travel limit switch of the machine tool, and the user has no feedback on this aspect.

4.檢測方法不正確,導致精度超差

4. The detection method is incorrect, resulting in an out of tolerance accuracy

檢驗員采用千分表配合磁力表座,以工作臺直線導軌滑座為檢測基準進行檢測,檢測方法及檢測基準也符合要求。

The inspector uses a dial indicator in conjunction with a magnetic meter base to conduct the inspection using the linear guide rail slide of the workbench as the inspection benchmark. The inspection method and inspection benchmark also meet the requirements.

5.裝配工藝不正確,造成裝配誤差

5. Incorrect assembly process, resulting in assembly errors

精密滾珠絲是數控設備上廣泛使用,由控制系統發出的脈沖信號控制伺服電機的旋轉,再由精密滾珠絲杠將伺服電機的旋轉運動轉換成工作臺的直線運動,從而實現工件的加工軌跡控制。因此,裝配工藝及精度檢測都很嚴格,對裝配工人的技術要求也較高。您對此有什么就來我們網站http://www.306135.com咨詢吧!

Precision ball screw is widely used in CNC equipment. The pulse signal sent by the control system controls the rotation of the servo motor, and then the precise ball screw converts the rotational motion of the servo motor into linear motion of the workbench, thereby achieving the processing trajectory control of the workpiece. Therefore, the assembly process and accuracy testing are very strict, and the technical requirements for assembly workers are also high. If you have any questions about this, please come to our website http://www.306135.com Consult!

- 上一篇:同步帶輪的重要性表現在什么地方

- 下一篇:導軌絲杠的原裝配步驟及裝配工藝問題

導軌絲杠:從設計結構...<>

導軌絲杠:從設計結構...<> 大型絲杠的性能設計介...<>

大型絲杠的性能設計介...<> 梯形絲杠和滾珠絲杠的...<>

梯形絲杠和滾珠絲杠的...<> 滾珠絲桿目前的行業的...<>

滾珠絲桿目前的行業的...<> 滾珠絲杠螺母油封更換...<>

滾珠絲杠螺母油封更換...<>

相關: