導軌絲杠:那些藏在精密傳動背后的 “硬核挑戰”

來源:http://www.306135.com/ 日期:2025-06-20 發布人:

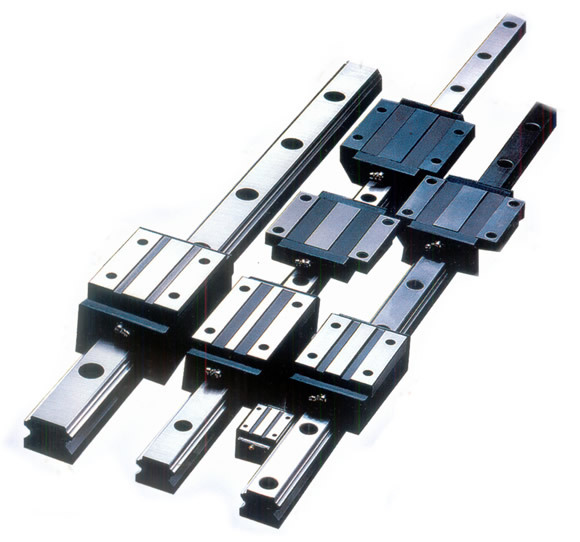

在機械制造的精密世界里,導軌絲杠如同設備的 “關節” 與 “肌肉”,承擔著精準定位和傳動的重任。然而,想要打造出性能的導軌絲杠并非易事,從材料選擇到加工工藝,從精度控制到潤滑維護,每一個環節都暗藏技術難點,稍有不慎就可能影響設備的整體性能。

In the precision world of mechanical manufacturing, guide screws are like the "joints" and "muscles" of equipment, bearing the responsibility of precise positioning and efficient transmission. However, it is not easy to create a high-performance guide screw. From material selection to processing technology, from precision control to lubrication maintenance, every link hides technical difficulties, and even a slight mistake may affect the overall performance of the equipment.

材料性能與加工工藝的平衡是首要難題。導軌絲杠需要具備高強度、高耐磨性和良好的尺寸穩定性,以承受長時間的負載與摩擦。但常用的合金鋼、不銹鋼等材料,硬度高的同時也增加了加工難度。例如,在車削、磨削過程中,過硬的材料容易導致刀具磨損加劇,降低加工效率,甚可能因切削力過大引發工件變形。而采用熱處理提升材料性能時,若工藝參數控制不當,又會出現內部應力分布不均,導致導軌絲杠在使用過程中發生扭曲或變形。此外,為了滿足高精度要求,部分導軌絲杠需要進行表面處理,如淬火、鍍硬鉻等,但這些處理工藝不僅要保證表面硬度和耐磨性,還要確保處理后尺寸精度不受影響,這對工藝控制的要求極高。

The balance between material properties and processing technology is the primary challenge. The guide screw needs to have high strength, high wear resistance, and good dimensional stability to withstand long-term loads and friction. However, commonly used materials such as alloy steel and stainless steel have high hardness but also increase processing difficulty. For example, in the process of turning and grinding, hard materials can easily lead to increased tool wear, reduced machining efficiency, and even deformation of the workpiece due to excessive cutting force. When using heat treatment to improve material properties, improper control of process parameters can result in uneven internal stress distribution, leading to twisting or deformation of the guide screw during use. In addition, in order to meet high-precision requirements, some guide screws need to undergo surface treatment such as quenching, hard chrome plating, etc. However, these treatment processes not only ensure surface hardness and wear resistance, but also ensure that the dimensional accuracy after treatment is not affected, which requires extremely high process control.

精度控制堪稱導軌絲杠技術的 “核心戰場”。無論是直線度、平行度,還是螺距精度,哪怕是微米級的誤差,都會在設備運行時被放大,影響終的加工精度。以滾珠絲杠為例,其螺旋槽的加工精度直接決定了傳動的準確性,若螺距誤差過大,會導致設備在定位時出現偏差。傳統的加工方法難以滿足高精度需求,需要采用的數控機床和高精度磨削設備,但即便如此,環境溫度變化、設備振動等外界因素仍可能干擾加工過程,導致精度波動。而且,導軌絲杠的裝配過程同樣對精度有嚴格要求,各部件之間的配合間隙、安裝位置的校準等,任何一個細節處理不當,都可能讓前期的高精度加工功虧一簣。

Precision control can be regarded as the "core battlefield" of guide screw technology. Whether it is straightness, parallelism, or pitch accuracy, even micrometer level errors will be amplified during equipment operation, affecting the final machining accuracy. Taking ball screw as an example, the machining accuracy of its spiral groove directly determines the accuracy of transmission. If the pitch error is too large, it will cause deviation in the positioning of the equipment. Traditional processing methods are difficult to meet high-precision requirements and require the use of advanced CNC machine tools and high-precision grinding equipment. However, even so, external factors such as environmental temperature changes and equipment vibration may still interfere with the processing process, leading to precision fluctuations. Moreover, the assembly process of the guide screw also has strict requirements for accuracy. Improper handling of any detail, such as the fit clearance between components and the calibration of installation positions, may result in the failure of high-precision machining in the early stage.

潤滑與防護技術也面臨諸多挑戰。導軌絲杠在高速運轉過程中,需要良好的潤滑來減少摩擦、降低磨損、延長使用壽命。然而,不同的工作環境和負載條件對潤滑要求差異很大。在高溫環境下,潤滑油容易揮發、變質,失去潤滑效果;在粉塵、切削液等污染嚴重的環境中,潤滑油又容易被雜質污染,導致滾珠或滑塊磨損加劇。因此,選擇合適的潤滑劑和潤滑方式關重要,但目前市面上的潤滑劑很難同時滿足耐高溫、抗污染、長壽命等多種需求。此外,防護裝置的設計也不容忽視,既要保證防護效果,防止外界雜質侵入,又不能影響導軌絲杠的正常運動,這對防護結構的設計和材料選擇提出了很高的要求。

Lubrication and protection technologies also face many challenges. During high-speed operation, the guide screw requires good lubrication to reduce friction, wear, and extend its service life. However, different working environments and load conditions have significant differences in lubrication requirements. In high temperature environments, lubricating oil is prone to volatilization, deterioration, and loss of lubrication effect; In environments with severe pollution such as dust and cutting fluid, lubricating oil is easily contaminated by impurities, leading to increased wear of ball bearings or sliders. Therefore, choosing the appropriate lubricant and lubrication method is crucial, but currently available lubricants on the market are difficult to simultaneously meet multiple needs such as high temperature resistance, pollution resistance, and long lifespan. In addition, the design of protective devices cannot be ignored. It is necessary to ensure the protective effect, prevent external impurities from entering, and not affect the normal movement of the guide screw. This puts high demands on the design and material selection of protective structures.

疲勞壽命與可靠性提升是長期存在的技術瓶頸。隨著機械設備向高速、重載方向發展,導軌絲杠面臨的負載和交變應力越來越大,容易出現疲勞磨損和斷裂等問題。雖然通過優化材料和結構設計可以在一定程度上提高疲勞壽命,但想要實現質的突破并非易事。例如,在復雜的工況下,導軌絲杠各部位的受力情況十分復雜,難以通過理論計算準確預測疲勞壽命,需要依靠大量的實驗和數據積累。而且,即使在設計階段考慮了各種因素,實際使用過程中的工況變化、安裝誤差等也可能導致可靠性下降,如何建立有效的監測和預警機制,提前發現潛在故障,也是行業亟待解決的問題。

Fatigue life and reliability improvement are long-standing technological bottlenecks. With the development of mechanical equipment towards high speed and heavy load, guide screws are facing increasing loads and alternating stresses, which can lead to problems such as fatigue wear and fracture. Although optimizing materials and structural design can improve fatigue life to some extent, achieving a qualitative breakthrough is not an easy task. For example, in complex working conditions, the stress situation of various parts of the guide screw is very complex, and it is difficult to accurately predict the fatigue life through theoretical calculations, which requires a large amount of experiments and data accumulation. Moreover, even if various factors are considered during the design phase, changes in operating conditions and installation errors during actual use may lead to a decrease in reliability. How to establish an effective monitoring and warning mechanism to detect potential faults in advance is also an urgent problem that the industry needs to solve.

本文由導軌絲杠友情奉獻.更多有關的知識請點擊:http://www.306135.com真誠的態度.為您提供為的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from the guide screw For more information, please click: http://www.306135.com Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

導軌絲杠:從設計結構...<>

導軌絲杠:從設計結構...<> 大型絲杠的性能設計介...<>

大型絲杠的性能設計介...<> 梯形絲杠和滾珠絲杠的...<>

梯形絲杠和滾珠絲杠的...<> 滾珠絲桿目前的行業的...<>

滾珠絲桿目前的行業的...<> 滾珠絲杠螺母油封更換...<>

滾珠絲杠螺母油封更換...<>